|

SY "GYDA", a 47 feet sail yacht made of raw, unvarnished aluminum.

Dubbel & Jesse Yacht Yard at Norderney, Germany, specialized in building aluminum sailing yachts up to 120 feet. All commissioned directly form the customers, mostly bluewater cruisers, but they also built yachts participating in regattas around the world, like the Vendeè Globe

The shipyard developed a specialized technique that enabled them to create hulls that was completely smooth, without any buckling or having to smooth and paint to cover the weld joints. The parts were first cut and pressed to the shape they would have before they were welded to a skeleton of ribs and girders. They could therefore deliver boats without any painting scheme, which makes maintenance much easier, something essential for a long distance sailor. Several other well-known shipyards have also seen the advantages of this and now deliver aluminum boats with no paint on the hull, such as Alubat and Allure, to mention a few.

Dubbel & Jesse later decided to focus more on the growing cruising market, and in cooperation with the yacht designers Judel / Vrolijk & Co, they created a solid, but fast yacht at 47 feet, with a swing keel. Construction material was, of course, seawater-resistant aluminum.

The owners were to a large extent invited to partake in the development of their own boat. The yard was open for visits and participation from the customer, so that the final result, as far as possible, was according to the plans and specifications of the buyer. Gyda's first owner had a strong focus on safety at sea, and the boat is made very sturdy and strong and she feels extremely stable and safe while sailing. The yard was unfortunately closed a few years ago.

Read the dramatic story when “Gyda” and the previous owner were attempted hijacked off the coast of Brazil in 2007. Here the extra strength built into “Gyda” really paid off:

S/Y Gyda reisebrev nr. 12, piratangrepet......

Click on the picture to enlarge and see the mark after the

hijackers bullet.

Winter at the harbour of Tornes, and at anchor in Golmvågen, both located on the north west coast of Norway

The human side of "Gyda"...

We want to explore the northern areas of the Norwegian coast, the Shetland and Faroe islands and Iceland. Later on we plan to go to Svalbard and Greenland.

To do this we needed a well built, fast and safe boat. Gyda has proven that she has these qualities through her eight years of sailing where her previous owner took her to the Falklands Islands, around Cape Horn, into the fjords of Patagonia, as well as the Caribbean, South America, Galapagos and Easter Island.

When she came up for sale we knew that if any, this was the boat that could make us able to realize our plans.

Who are we?

Skipper Ingvild, is a trained aviation navigator in the Royal Norwegian Air force. Responsibilities on board: Chief Planning, Chief Navigation, Chief fender and mooring, Chief galley, head of nursing and care, Chief "ehhem ... there is something I have to ask .. ". To make it short; Chief of just about everything.

Captain on board is Henrik, a rescuer with the Norwegian Air Ambulance, spending time on land, at sea and in the air. Responsibilities on board: (these are in addition to the job as the ship captain) fix any problem and answer any question the skipper may have. In return, a grateful recipient of the skipper’s TLC.

We have both: D5L Recreational Skipper Certificate and D5LA Astro / Offshore Skipper Certificate.

VHF SRC certificate.

A wide range of PADI diving certificates.

Captain Henrik also holds: CEVNI channel certificate for the internal European inland waterways,

IANTD certificates of technical deep diving and

Rescue diving class S. Certificate.

The Skipper holds the Maritime HF / LRC radiotelephony certificate

The technical side of "Gyda"...

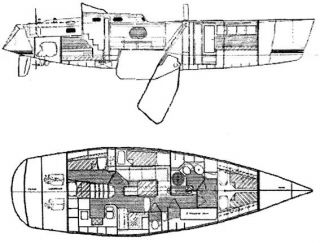

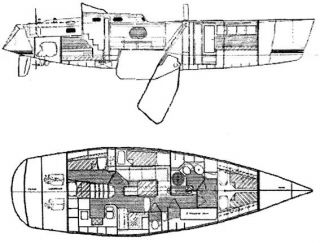

Type: Nordsee 47 swing. “Gyda” is 14.5 m long, 4.3 m wide and the depth can be varied between 1.10m - 3.10 m.

She is constructed in seawater-resistant aluminum of variable thekness. From 10mm in the bow, along the keel and in the keel box, 8mm in the hull below the waterline and 6mm in the hull above the waterline and the deck and the doghouse.

General technical info:

Why aluminum? We have long been convinced that aluminum was the material we wanted for our yacht. The reasons are several, but the main reason is its great strength; Compared with other materials aluminum is, on strength–to-weight ratio, the strongest non-toxic material available. It has about 45% greater tensile strength than steel. This makes “Gyda”'s hull, which in weight is as heavy as an equivalent size steel boat would have been, almost 50% stronger! Other aluminum builders, for instance Alubat and Allure, do the reverse. They build boats that are almost as light as fiberglass boats, and almost as strong as steel boats, getting the better of two worlds.

· In the case of a collision, the aluminum will stretch and bend more easily than steel before it ruptures.

· In addition, the sturdy skeleton onto which the hull plates are welded contribute to increased strength, and none of the braced bulkhead inside are part of the main structure of the boat. Hence, you may alter and customize the layout of the interior without affecting the structural strength of the boat.

· Although the aluminum is somewhat more expensive than steel in the acquisition phase, its maintenance is considerably cheaper. Especially if you keep the boat with no paint or varnish, like “Gyda”. Seawater-resistant aluminum oxidizes to form a dull gray coating on the outside of the metal. The Oxidation protects the aluminum and stops further corrosion. Since we do not need to take paint damage or scratches in the gel coat into account, it doesn’t worries us if we must moor at a pier with a large truck tires along the sides. There is no such thing as polish onboard, and we are totally relaxed regarding unsightly marks, and if they start getting on our nerves, they can easily be sanded away. The spring preparation above the water line consists of a quick swipe with a water hose to chase away the sand and dust from corners. That's it.

There are many hearsay stories about aluminum boats that have almost disintegrated from corrosion. This are remains of fanciful horror stories. It’s true that owners of aluminum boats must pay extra attention to the electrical system, and ensure that it is properly insulated and expertly executed. “Gyda” is epoxy treated on the inside of the hull to reduce the possibility of malicious corrosion.

All bushings are strongly welded, with tubes long enough to go well above the water table, reducing the risk of leakage from a leaking valve or hose clamp. It is also every reason to look to the thousands of aluminum boats that for years have been working in the fish farming industry, rescue services, the Navy, transportation, fishing, etc. There are no reports of a single one of them sinking as a result of corrosion.

Unlike plastic boats, which often have a sandwich construction with a tiny diviny cell or balsa core insulation, aluminum boat need to be properly insulated on the inside. This provides a range of benefits in addition to cold/ heat problems, and noise. Noise from road traffic near the harbor, party in the neighboring boat or clutter while sailing is dimmed considerably. “Gyda” is built for sailing in Arctic climate and has 6 cm insulation from well below the waterline all the way around the deck. A pleasant side-effect of this is that the ship also remains cool during a burning sun.

Comfort:

Since we are primarily thinking of Arctic sailing, we need to know that the boat is warm and dry. “Gyda” has a Taylor mod. 089 oil furnace in the lounge and a Taylor Mod. 030 oil-stove in the galley which account for part of the heating on board. Furthermore, we have built a unique radiator heating system that heated by a Webasto Thermo 90 ST water heater . We also have a Taylor oil furnace in the lounge. The result is a thoroughly warm and dry boat with radiator heat in the cabins, saloon, galley and the bathroom, which also has become a great drying room. Otherwise, the Taylor's cooker in the galley is also used for heating as it has three oil burners and therefore is very effective at drying the air inside. Ther are no gass onboard Gyda.

There are two toilets on board. One with Rheinstroms Y2RG manual pump, the other a Jabsco with electrical pump. The black water can go either directly into the sea or to a holding tank. In addition to hot and cold tap water in the head, the day toilet and the galley, there are manual seawater pumps to all sinks, and a manual fresh water pump in the galley. The galley is equipped with a refrigerator and a freezer.

To make the voyage in cold regions more comfortable we had an aluminum doghouse welded on as an integral part of the superstructure. The windows are made of laminated glass. The cockpit area can be totally enclosed by a canopy, and makes the entire cockpit warm and wind protected.

Electrical:

Both engines have two generators each. One 12V exclusively charging the engine starting battery and one Master Volt Alpha 24V / 75 Amph charging the consumer bank, which holds approximately 600 Amph. Hence, no matter which engine is running, the charging of the consumer bank will be ensured. Charging of the start and consumer batteries when on shore power is taken care of by a Mastervolt charger. Our need for 220V is taken care of by a 2500w Victron Inverter. Furthermore we have a Air-X 400W wind generator and a tow Aqua4gen generator to provide electricity while sailing or at anchor. All lamps and lights have LED bulbs

Simrad Robertson AP20 autopilot with AP21 remote control, Grundig radio / stereo, Inmarsat-C satellite receiver with a Thrane&Thrane modem for satellite mail, Iridium 9555satellite phone with a DK-075 docking station, one stationary Digitalyacht AquaPro navigation computer connected to the Furuno NN3D chart plotter in the cockpit, a couple of lap tops, Watermaker Katadyn Power Survivor 160E PS, Lewmar Ocean3 2000W windlass

Navigation:

Furuno NavNet3D 12 "MFD Chartplotter with 4 kw 3D Furuno radar, Furuno DFF3 sonar, Furuno Fax 30 Navtex / WX fax and Furuno FA-50 AIS, Furuno SC 30 GPS compass, Furuno GP33 stand alone gps, MaxSea Explorer computer navigation at the navigation desk, down linked to Furuno Network, B&G Hydra 2000 sailing instruments with wind info, log, speed and depth, Icom IC603 DSC VHF with remote controll in cockpit, Icom IC-801E HF/SSB tranceiver.

The Windpilot Pacific PlusII on it's way back Viking RescYou PRO and EPIRB mounted on the pushpit

on the transom after being overhould by the factory

in Germany.

Safety:

60 meters of 13mm stainless steel chain and a 70 lbs Spade anchor. In addition, we bring one original 60lbs BRUCE anchor and a 70lbs Spade, as groundtackle for the spare anchor we have 10 mtrs of 13mm chain and a AMG 8/150 Easyroll coil with 150 meters of 8 tons flat line. 2 pieces of Simrad HT50 handheld VHF, 1 TRON 45SX and 1 TRON 40 GPS MK II EPIRB beacons w / FB-5 free float bracket, VIKING RescYou Pro liferaft, Signal gun, signal rockets(er du sikker p dette er riktig betegnelse?), 6x red and 6x white flares and 4x signal smoke. 100W 24V handheld spotlight, 50W diving torch.

Automatic electric bilge pumps with level switches in each of the three separate watertight sections on board. Manuel bilge pump operated from cockpit. Granny-bars on both sides of the mast for increased security while sailing.

Testing the survival suits. All survival suits are insulated to give extra protection in harsh climate

Firefighting: 4 x 2 kg foam, 2 x 6 kg CO2 (for engine), 2x fire blanket in the saloon and galley, 5 personal immersion suits, 8 x Lifejackets, 2x SpinLock inflatable life jackets with safety harness, Active radar reflector, Garmin handheld GPS 76.

Maneuvering:

2x Yanmar diesel engines 4J3BE, 2 liter, 52 bhp. The engines are considered highly reliable. Since they have natural aspiration (no turbo). Each engine is connected to a Yanmar SD31 sail drive with Flex-O-Fold propellers. Sleipner SE 120/215 Twin IP 8 , 5 hp bow thruster.

The swing keel that weighs 10.000 lbs is controlled by an electro-hydraulic pump, which swings the keel and secures access to shallower waters.(max keel depth 3.1meters, min depth 1,1meter

Rig & Sail:

Stainless steel wire 14mm, 10mm diagonals, Z-Spar aluminum mast, Genakker 145m2, Quantium Genoa 65m2 and jib 15 m2 on roller furler, fully battened Quantium mainsail 55 m2 from with Harken runners.

Winches: 2 Lewmar 48ST winches at the mast, 2 Lewmar 48ST , 2 Lewmar 56ST and 2 Lewmar 64ST in the cockpit. Lazy Jacks, climbing steps in the mast, spinnaker boom x 2 fitted on the mast. Gyb'easy bombrake. Heavy duty Milwaukee 28V right head, hand held cordless drill equpied with a WinchBit acts as our "electrical power winch" on any of the winches where it's needed. (gives tremendes force to the winch)

Fuel & water:

The total fuel capacity is 2000 liters of diesel including the manually filled day-tank containing about 40 liters. The main idea with the day tank is easily accessible drain at the bottom where water and dirt can accumulate. There is also a hose faucet for filling cans, for instance for the Taylor oil stove in the lounge. Total capacity of fresh water is 600 liters.

----------------------------------------- /////---------------------------------------------------

|

LINKER:

Weather services:

Blue water sailors:

Wandering Albatross

---------------------------------------------------------

Here youcan see some of the technical

solutions chosen. Gyda was built to satisfy

the German -Lloyd's specifications for

ocean-going yachts, and is CE certified

class A-open sea.

The engine room with two 52 bhp. Yanmar 4JH3E natural aspiration (no turbo) engines, Each engine are connected to a Yanmar SD31 saildrive.

Each engine has a double mounting of Racor diesel filters.

40 ltrs day tank

With the keel down “Gyda”s drought is 3.10 m maximum and with raised keel 1.10 m at the minimum. There is a valve ensuring the keel will swing up if run aground. Another important safety detail is that if the boat should capsize in the water, a valve will automatically close to prevent the keel from seeping down into the keel box. In that way it remains standing up maintain the righting forces to get the boat back in normal position again.

The Yanmar SD31 saildrives are protected against ice and other

floating objects by solid ice protection fins in the front. The

Flex-o-fold propeller, positined right in front of each rudder,

ensures good maneuverabilety. Here you also see the auxiliary rudder of the Windpilot.

The bow spear is seen mounted.

Hard dodger, or a doghouse as it my also be called, will provide shelter and protection during the voyage. Since it is built in 6mm aluminum and double hardened windows, it should withstand the beating from rough seas without kneeling. Under engine or at anchor the canopy ensures wind and rain protection and keeps the cockpit warm and dry.

At the rear is seen the life raft on the port side, tug generator just under the mounting plate for the outboard. On the targa the wind generator, the antennas for the NAVTEX, active radar reflector, Inmarsat-C, ICE-mobile WiFi network, GPS compass and GPS antenna are mounted, as well as navigation lights and working lights for the cockpit.

Gyb'easy bombrake

VIKING RescYou life raft was purchased early 2010 when the previous raft expired and we wanted one that was made for tougher climate and arctic conditions.

Tron GPS 40 MK II, GMDSS EPIRB mounted with

FB5 Free Float bracket. The battery capacity is

guaranteed to more than 48 hours in -20°C.

It will calculate and send it’s first position

message less than 3 minutes after activation

(TTFF <3).

Sleipner 120/215 Twin IP bow thruster. The engine is located in the bow room where there may be some spillage of water through the hatch. Therefore we have chosen Sleipner IP type, which is completely sealed, waterproof and spark proof, so it can withstand such an environment. The fact that it is completely spark proof allows us to keep gasoline cans in this room as well.

New mainsail June 2010, New Genoa 2011 Quantium CX P9 Pentex, delivered by the Maritime Company, in Trondheim

SPADE 55 kg anchor delivered by Finisterra.

Lewmar Ocean3, 2000W windlass, 60m 13mm stainless anchorchain

Chainlock made by Arild at BWS's. Velded to the superstructure, solid as rock.

New propellers, MaxProp FAST 4 blade was mounted to increase the backing performace, which was really bad with the old folding propps. |